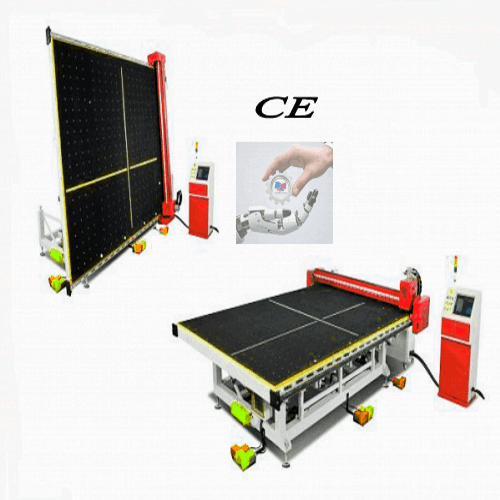

CNC Tile-top Glass Cutter

Applications of CNC Tilt-top Glass Cutter

The CNC glass cutting machines with pneumatically tilted loading tables have a wide range of applications. They are used in fields such as construction, automotive, furniture, electronics, and handicraft glass. These machines can accurately cut various types of glass, including those for doors and windows, curtain walls, car windows, furniture tabletops, display screens, decorative and artistic glass, meeting different requirements for shapes, sizes, and precision, and facilitating the forming of products.

Advantages of CNC Tilt-top Glass Cutter

1.Efficient Loading

- Quick & Precise Positioning: The pneumatic system powers rapid tilting. When handling glass, it instantly adapts the table's angle to match the glass, slashing manual adjustment time and upping placement accuracy.

- Thickness Adaptability: Pneumatic control fine-tunes suction and tilt as per glass thickness. This means any thickness of glass can be securely held, preventing slips during transfer.

2.Cutting Precision

- Stable Setup: The tilted loading table steadies the glass while cutting. Less shaking enables the cutting head to stick to the planned path, enhancing precision and cut quality.

- Custom Angles: Operators can tweak the table's angle for special cuts like bevels. This meets unique customer demands, adding value to the final glass products.

3.Enhanced Safety

- Protect Workers: Safety devices on the tilting system sense obstacles or people, halting movement to dodge collisions. Less manual handling also cuts the risk of operator injury.

- Protect Equipment: Pressure sensors and overload guards stop the system if pressure spikes. This safeguards components, extending the machine's lifespan.

4.Greater Versatility

- Multi-Glass Compatibility: By adjusting settings and swapping parts, these machines handle various glass types, from tempered to float glass. This universality saves on equipment costs.

- Easy Integration: Their simple structure allows seamless connection with other gear, building automated lines for glass loading, cutting, and blanking. Efficiency and profits soar.

5.Lower Maintenance

- Less Wear: Compared to electric or hydraulic drives, the pneumatic system has fewer moving parts. This leads to less mechanical wear, fewer repairs, and less downtime.

- Simple Troubleshooting: Pneumatic faults are straightforward to diagnose. Regular maintenance staff can quickly spot and fix issues with basic checks, cutting both costs and repair complexity. Overall, these machines boost productivity across the glass-cutting process.